A garment manufacturing quality management system (QMS) is related to quality control and assurance system that documents (quality manual) processes (Online and offline), procedures, system, planning, responsibilities, and task for achieving quality goals and policies to meet buyer requirements. A quality management system is focused on customer requirements and satisfaction through combine effort of whole organization management by setting up a work standard.

Contents hideA quality management system helps a factory to coordinate and instruct an organization’s functions/activities to meet buyer requirements and improve its effectiveness and efficiency on a continuous basis quality control and improvement. Good quality management can guide a factory to the right path of quality goal, to keep standard of export garments quality; a good quality management system should be implemented.

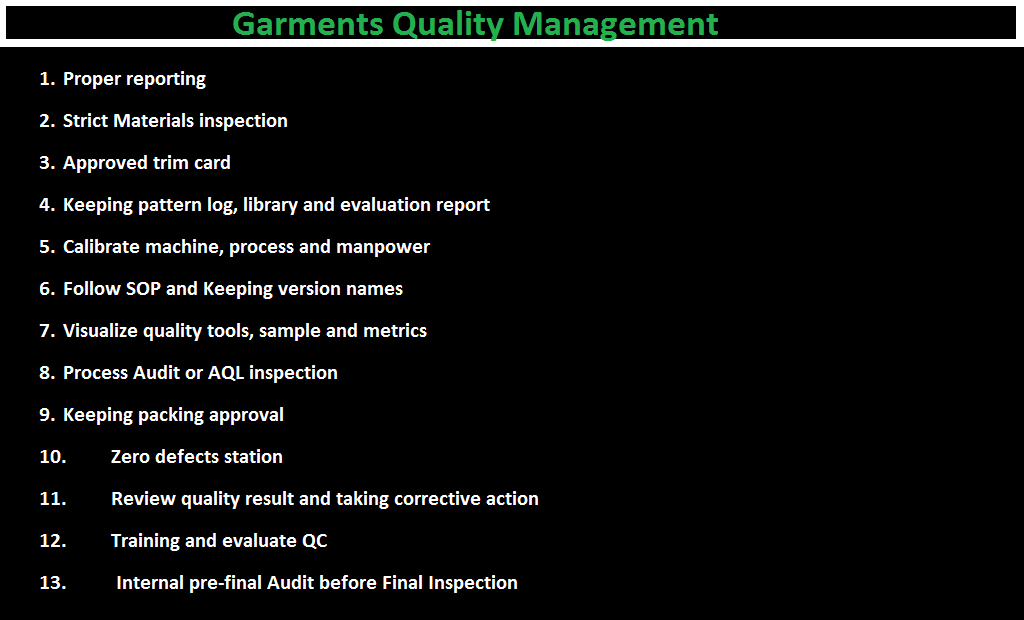

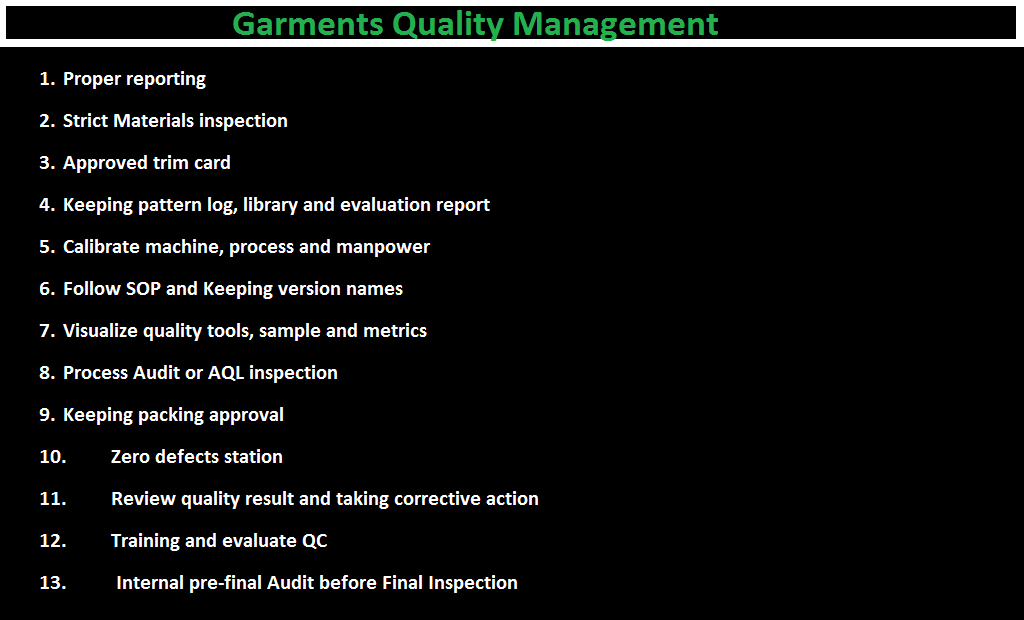

Quality department’s first responsibility is reporting, and then taking action. If they report is doing properly, easy to work on it.

Most of times needed raw materials like fabrics; accessories of a garment need to buy from a supplier, so it’s important to inspect all raw materials and ask supplier if there any defects. Because once you make a garment, it’s almost impossible to replace if their faulty fabrics or trims.

Following approved Trim card in store, cutting, sewing and finishing ensuring correct materials and fabrics are joining for every lot.

Pattern is very sensitive, standard is to keep a pattern library, track and change log of every stage as like before and after size set.

Yearly or half yearly calibration of machines to check machine is fit enough, performing well or not. Need to check calibration by 3 rd party or machine supplier of CAD plotter, Fabrics inspection machine, shading checking light box, Fusing machine, needle detector machine, pull testing machine and others lab testing machines.

Follow a SOP for every process and section, keeping SOP change log and version name. ISO method is to keep SOP version name.

Visualizing all quality tools, analysis, and quality metrics will make aware about everyone’s performance and responsibilities will help to take decision easily.

Inspection garments by AQL audit system before moving garments to next step or process to check process accuracy, passing goods from every section by passing in audit, if audit fail goods back for reprocessing.

A system to approve a garment by authorize person (buyer QC, merchandiser or QA manager) before start packing of every lot

Set up zero defect station by through 100% garments quality inspection in sewing and finishing.

Review every sections quality result by a daily or weekly basis and taking corrective action to not to happen and improve in the future. A general meeting can be called with related production and maintenance department and giving responsibilities to improve quality as a part of corrective action.

Training is one of the major part garments quality management, Kaoru Ishikawa said: “Quality control starts and ends with training.” Continuously train up whole quality team about various quality matters and evaluate their understanding.

Pre-final Audit or an audit before Final quality inspection procedure as per final inspection procedure to confirms final inspection will be passed of every lot.

Related articles you may love to read